We're open daily! View holiday hours

Science News

Magnetic Soap

January 26, 2012

Chemists recently announced the very first magnetic soap. Why magnetic soap you may ask?

The BBC answers:

Experts say that with further development, it could find applications in cleaning up oil spills and waste-water.

Scientists have long been searching for a way to control soaps (known as surfactants) once they are in solution. This would increase their ability to dissolve oils in water and then remove them from that system. A team at Bristol University has researched soaps sensitive to light, carbon dioxide and changes in pH, temperature or pressure. Their latest breakthrough, reported in Angewandte Chemie, is the world’s first soap sensitive to a magnetic field.

The team, lead by Julian Eastoe, produced the magnetic soap by dissolving iron in a range of inert surfactant materials composed of chloride and bromide ions, very similar to those found in everyday mouthwash or fabric conditioner. The addition of the iron creates metallic centers within the soap particles.

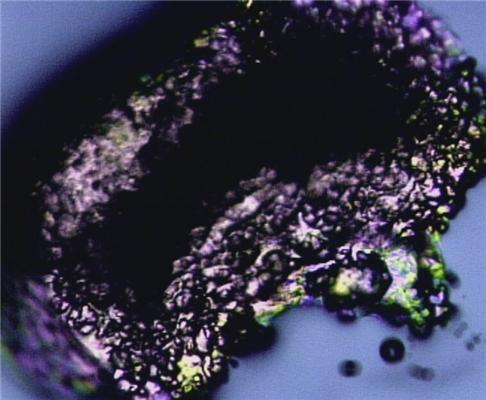

When surfactants are added to water they are known to form tiny clumps. Working with French scientists, the chemists used a technique called “small angle neutron scattering (SANS)” to confirm that it was this clumping of the iron-rich surfactant that brought about its magnetic properties.

Its magnetic properties make it easier to round up and remove from a system once it has been added, suggesting further applications in environmental clean-up and water treatment. Scientific experiments that require precise control of liquid droplets might also become easier with the addition of this surfactant and a magnetic field.

Eastoe remarks on the surprise of this finding, “As most magnets are metals, from a purely scientific point of view these ionic liquid surfactants are highly unusual, making them a particularly interesting discovery. From a commercial point of view, though these exact liquids aren’t yet ready to appear in any household product, by proving that magnetic soaps can be developed, future work can reproduce the same phenomenon in more commercially viable liquids for a range of applications from water treatment to industrial cleaning products.”

Image: Institut Laue-Langevin